The importance of preventative maintenance for chainsaws

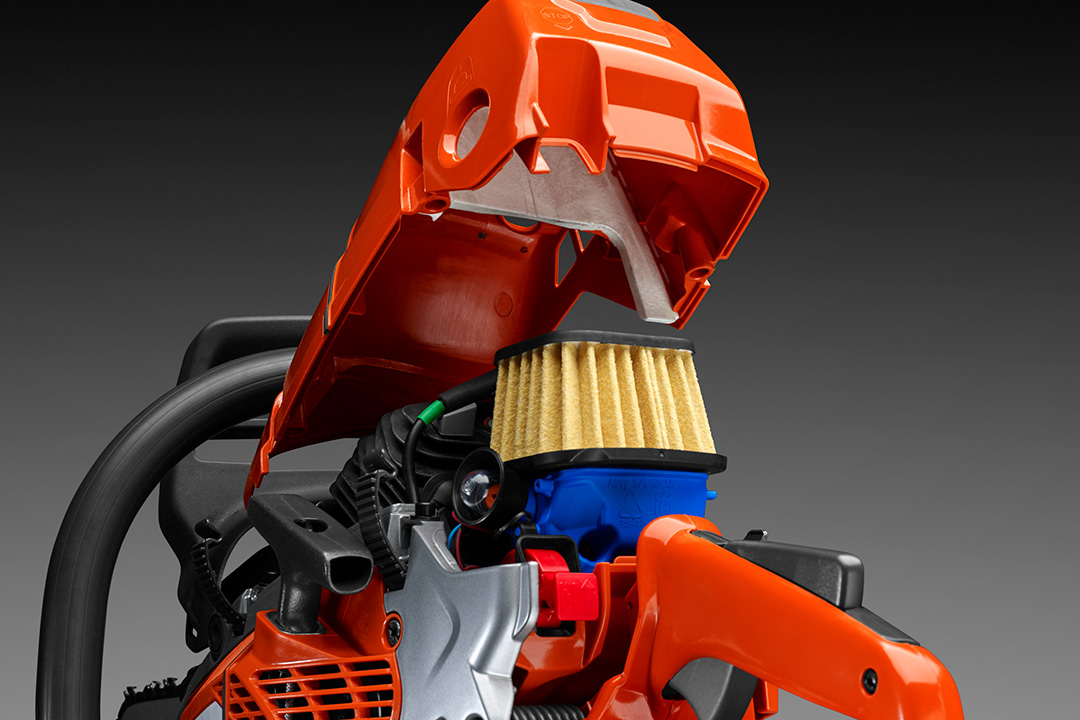

Chainsaws are powerful tools that play a crucial role in several industries, including forestry, gardening and construction. Husqvarna is a manufacturer and supplier of world-class chainsaws that are durable and reliable. However, these tools still require routine maintenance to ensure that they work properly, are safe to use and have a long lifespan.

Cutting Edge is the leading supplier of Husqvarna chainsaws in Zimbabwe. Our After Sales department and nationwide dealer network specialise in chainsaw repairs and services. We know how important preventative maintenance can be for extending the lifespan of a chainsaw and getting the best returns on your investment.

Why preventative maintenance matters?

Preventative maintenance is a proactive method that helps to avoid potential problems by examining, cleaning and servicing chainsaws on a regular basis – especially before the cutting season starts. Chainsaw owners can reap many rewards by implementing this precautionary practice.

Regular maintenance improves safety by lowering the likelihood of accidents caused by faulty parts. It also increases the efficiency of the chainsaw, allowing for smoother and more precise cuts, eventually saving time and effort. What’s more, proper maintenance helps to minimise costly and unexpected repairs, saving chainsaw owners money in the long run.

Zimbabwe has a diverse climate and topography, so chainsaws need to confront particular challenges. The components can be strained by high temperatures and dusty surroundings, as well as muddy and wet environments. As a result, routine and comprehensive maintenance is essential to ensuring optimal performance and longevity.

Maintenance tips for chainsaws

1) Thorough cleaning and inspection – Start by cleaning the chainsaw of any debris or residue. Pay special attention to the chain, guide bar and sprocket, as these regions frequently collect sawdust and debris. Examine the chain for wear and tear, sharpness and correct tension. Be sure that critical components, such as the guide bar, are free of damage or faults.

2) Check the lubrication – Lubrication is critical for decreasing friction and protecting chainsaw components. Use a high-quality bar and chain oil and apply it to the guide bar to ensure smooth operation. Make sure that you follow the manufacturer’s instructions for the proper lubricant and lubrication technique.

3) Chain tension adjustment – Inadequate chain tension can have a large impact on both performance and safety. A loose chain can jump off the guide bar, but an overly tight chain can put too much strain on the chainsaw’s motor. For optimal operation, check and adjust the chain tension regularly according to the manufacturer’s instructions.

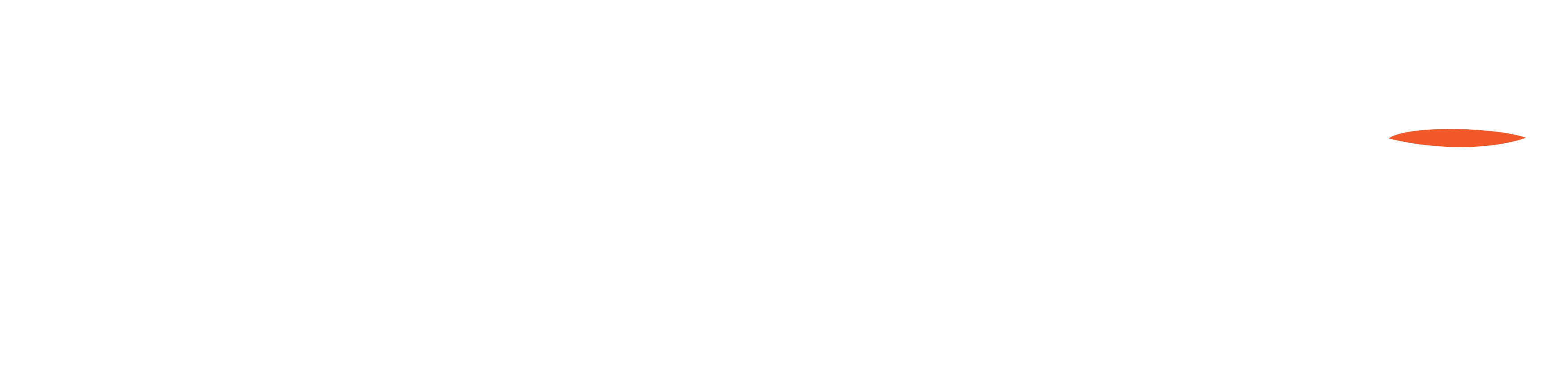

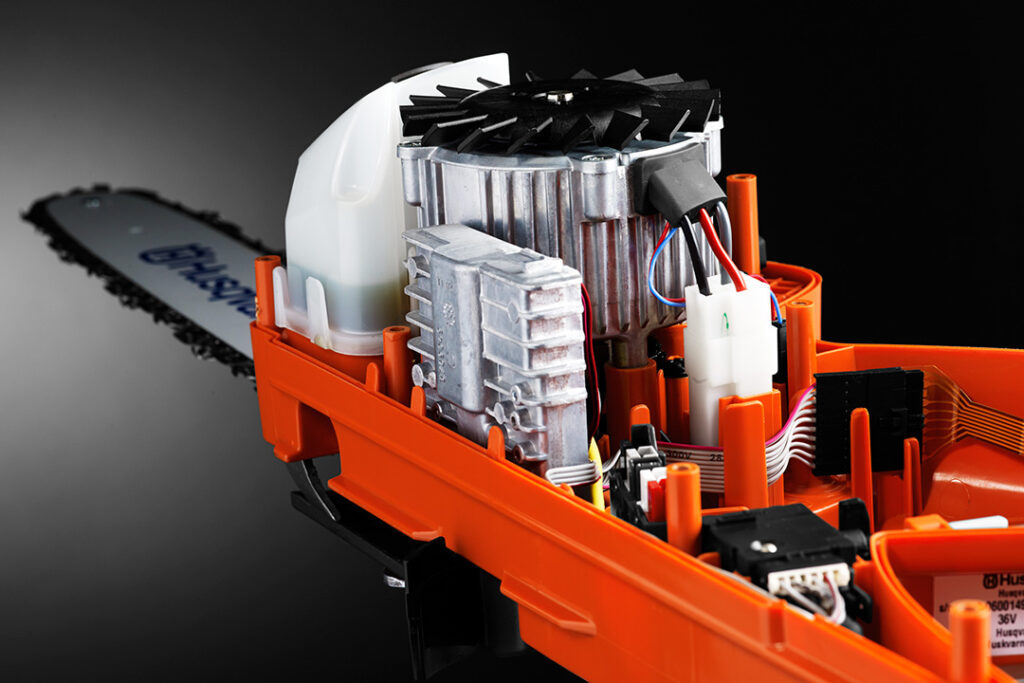

4) Check the air filter – The air filter in the chainsaw is critical for best engine performance. Inspect the air filter regularly for dirt, debris and obstructions. To guarantee proper airflow and minimise engine damage caused by dirt ingestion, clean or replace the air filter as needed.

5) Regular blade sharpening – A sharp blade is necessary for efficient cutting and decreasing chainsaw fatigue. Dull blades can cause more wear on the chainsaw’s motor and reduce cutting performance. To keep a sharp blade, follow basic safety practices and use the appropriate sharpening tools.

Additional maintenance tips

Aside from the key maintenance steps described above, correct fuel management, regular spark plug inspection and storage instructions are also critical. To avoid engine damage, use the appropriate fuel mixture ratio stated by the chainsaw manufacturer.

Regular spark plug inspection promotes efficient combustion and reliable starting. Proper storage, which includes cleaning the chainsaw, emptying the fuel tank and protecting it from the elements, aids in the prevention of corrosion and extends the lifespan of the chainsaw.

You can enjoy increased safety, efficiency and cost savings by following the measures mentioned above and sticking to additional maintenance practices. When troubleshooting chainsaw issues, always refer to the user manual.

Alternatively, you can contact Cutting Edge’s After Sales department or one of our dealers in a town near you for your servicing requirements. Cutting Edge is committed to offering both quality chainsaws and exceptional customer service as the provider of Husqvarna chainsaws in Zimbabwe. Feel free to contact us for any queries and information you require.

___

Cutting Edge is the leading supplier of Husqvarna products in Zimbabwe. We bring you the best tools in the business with world-class service and after sales care. Follow us on Facebook and Instagram for the latest news and product offerings from our brands.